Everything for additive manufacturing.

Heat treatment processes are also required in additive manufacturing. We would be pleased to support you in selecting the appropriate process and choose the optimal furnace for you!

Chamber furnaces - Tailored to your needs.

We plan and realise exactly the chamber furnace you need for your company: CE and CQI-9 compliant, with capacities from 5 kg - 1,500 kg for a combustion chamber with a volume of 2 l to 10 m³. The control of the kiln temperature (from 50 °C to 600 °C) is done by PLC, BDE, temperature controller or energy consumption measurement are of course also possible. Filling and emptying can also be semi or fully automated on request, in order to fully integrate the chamber kiln into running production and process chains.

Environmentally friendly.

When developing industrial furnaces, we pay attention to maximum Efficiency

and reliable performance. And much more, because our chamber furnaces

- with their low energy consumption are real energy savers and environmental protectors.

- represent an economic investment for the present and the future with a long service life.

- offer numerous application possibilities in industry and trade.

- enable simple maintenance and servicing, which reduces running costs and downtimes.

Thus we and our customers make an active contribution to environmental protection and save limited resources.

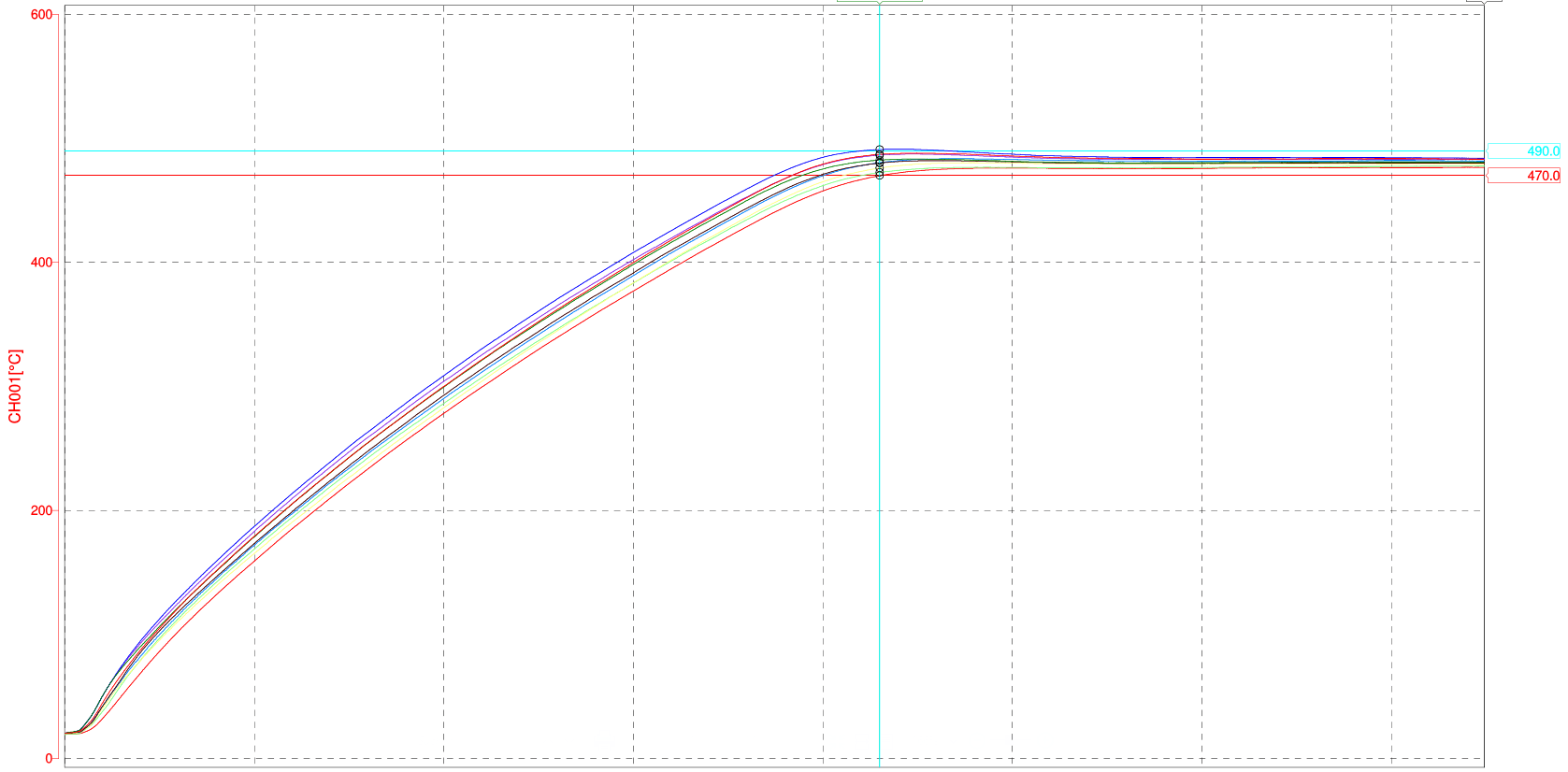

Highly accurate.

When it comes to the temperature in the furnace chamber, we take it very seriously: our chamber furnaces

not only cover a wide temperature range of 50 °C to 600 °C. They ensure that the set temperature is reached in the entire chamber area, and this reliably over the entire processing time. For you, this means controlled heat treatment

of your large, small or tiny workpieces in a chamber furnace from Dreisberg & Jungmann, over and over again.

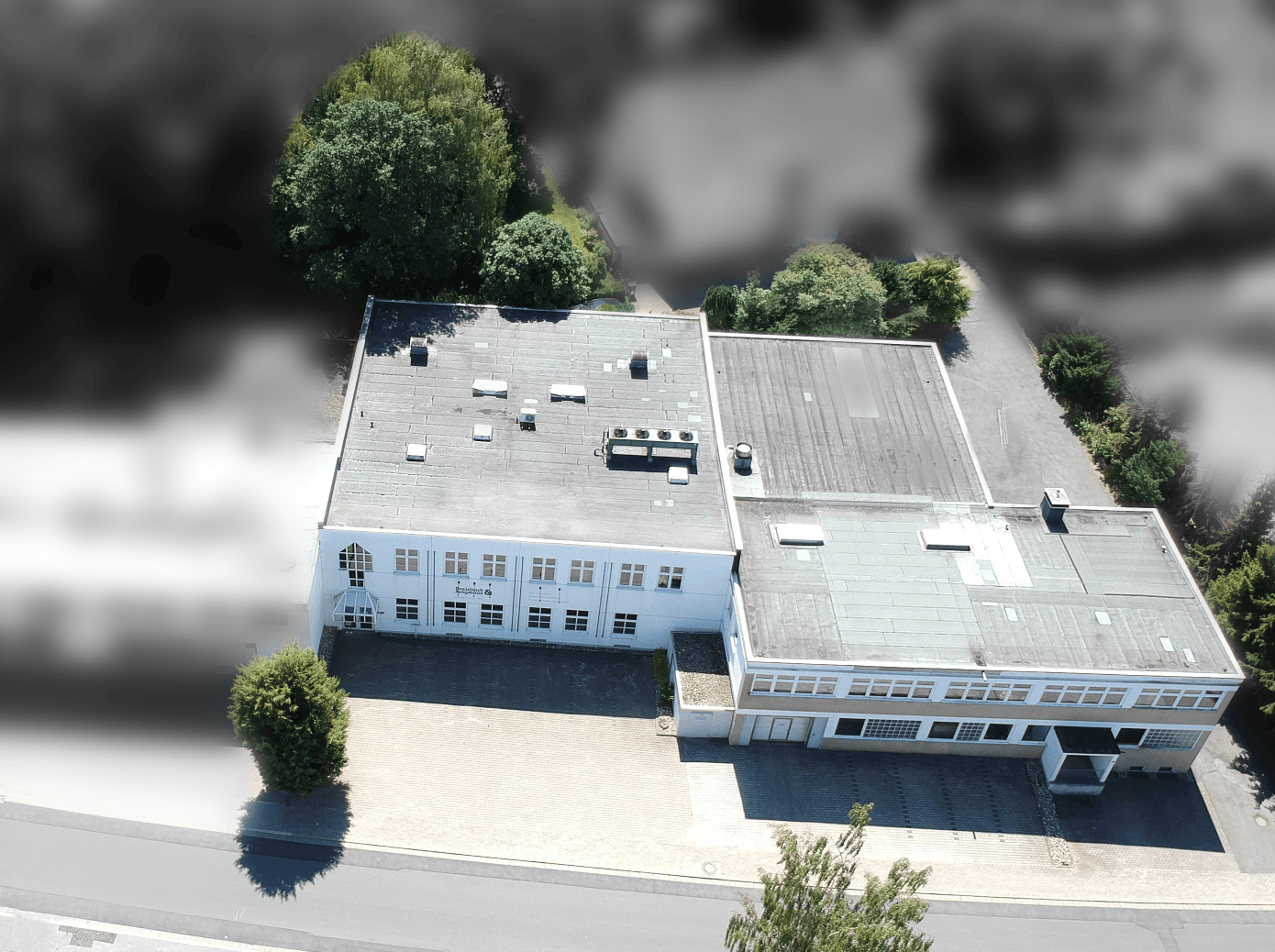

Product examples.

Below you will find a small selection of the chamber furnaces already manufactured.